So as to appropriately realize CNC precision machining, it really is vitally critical that a person understands its core elements:

The Okuma L B35II serves important industries like aerospace, automotive, and hefty machinery, emphasizing applications necessitating precision and trustworthiness partly production.

All it does is consider the spindle rotation and coordinates the feed this kind of that once the spindle can make a flip the Z slide will likely have moved .0625". My 2 more mature lathes with 3000 controls do not have a tap cycle, but I nonetheless tap with them merely by programming the motion from the tap into the outlet at an IPR feed, stopping at the desired depth, and reversing the spindle and feeding again away from the hole at exactly the same rate. This accomplishes a similar point as the tap cycle, but it surely does need that you choose to listen to owning the feed override set at one hundred% for your cycle For the reason that control is just not overriding and mechanically location it to a hundred as it is going to within the canned cycle. Occasionally I have cheated and held a tap rigid in the collet as an alternative to utilizing a T-C holder, and although I've by no means experienced a faucet crack as a result of doing this, it will eventually often cut the thread a tad looser than it ought to be, and does demonstrate the necessity for utilizing a T-C faucet holder.

This helps make them an economical option for providers wanting to increase their functions or men and women honing their craft without burning a hole inside their pockets. It can be really worth noting that the price of Lathes products may vary greatly according to their type, manufacturer, and certain features.

Torque control The torque control perform controls the motor to rotate at a particular level, with a specific second because the termination situation in the rotary movement.

Manual MST operate Users can start out MST commands in the posture screen in manual/MPG manner, which reduces web page switching and helps make the Procedure far more centralized and easy for users to swiftly work the machine

A CNC Grinder employs abrasive tools to easy and end a machined product. Grinders are typically used in apps requiring incredibly high precision for instance motor parts.

Integration: It employs software integration to generate highly specific and complex parts speedily and efficiently. Utilizing CAD/CAM software enables designers and producers to streamline the production procedures extra efficiently when making complex parts promptly.

Mazak turning centers are designed with a number of advanced features that significantly improve machining capabilities:

The protection industry demands parts with the highest levels of precision and toughness, frequently generated from tough-to-machine products. The GT Max Series multi-slide CNC lathe from Cubic Machinery is an excellent choice for defense applications, providing up to 3 simultaneous cuts from a few tool slides. This design allows for rapid production of complex parts with tight tolerances.

"The Okuma LB35II has exceeded our expectations with regard to precision and dependability. Highly advisable for all those from the automotive industry."

Thread restore function The thread repair service perform enables the machine to maintenance broken threads (significant oil pipelines or Learn more screw) regardless of whether the machine tool is equipped with a servo spindle or an analog spindle.

You could stretch that some on aluminum together with other tender materials, but I have in no way definitely noticed any info indicating exactly how much the depth really should be minimized for a fabric like 316. I did discover a encouraged speed of 30 fpm for variety tapping austenitic SS. I am not about to say its the worst, but it had been the bottom encouraged speed of any substance effective at staying form tapped.

By making use of CNC drilling machines, supplies can be processed at noticeably higher speeds in comparison with manual drilling techniques. In addition, modern day CNC drills integrate smart tool swapping and positioning systems, even more boosting their productivity.

Luke Perry Then & Now!

Luke Perry Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Jenna Von Oy Then & Now!

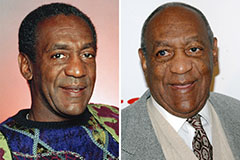

Jenna Von Oy Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!